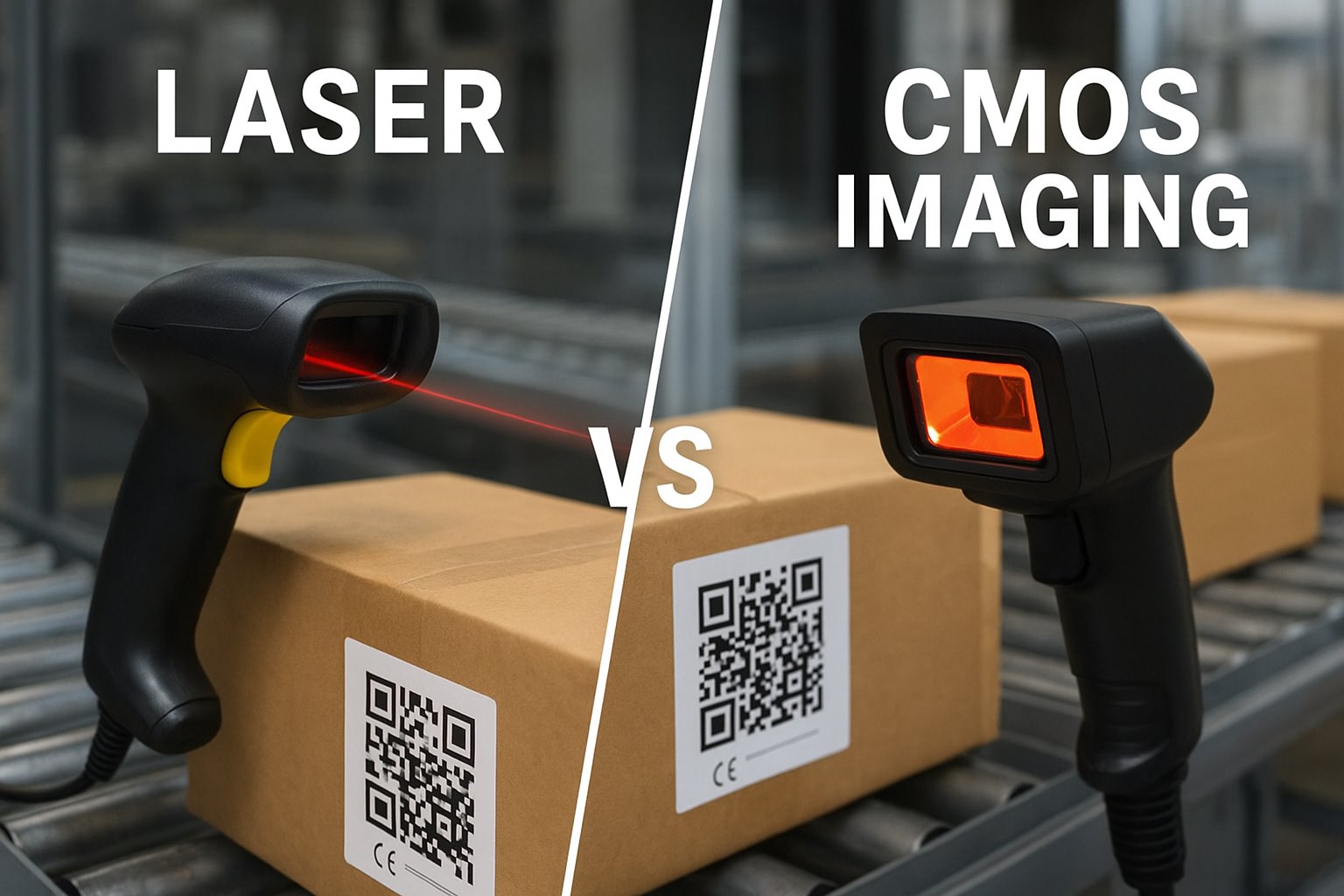

Trong môi trường công nghiệp, the reliability and efficiency of QR code scanning directly impact operational productivity. Chọn đúng mô -đun quét Laser hoặc CMOS, chi phí ảnh hưởng có thể, Độ chính xác, and long-term durability. While both technologies are integral to the modern landscape of industrial QR code scanners, their underlying mechanics and performance characteristics differ significantly. For manufacturers such as Lonvill, which designs and supplies high-performance scanning modules, understanding these distinctions is key to guiding clients toward the best solution for their needs.

The Role of Scanning Modules in Industrial Environments

Industrial QR code scanners are essential in logistics, manufacturing, warehousing, and quality control. They must decode barcodes under challenging conditions, including dust, low light, vibration, or fast-moving production lines. The scanning module serves as the core of these devices, determining reading speed, sự chính xác, và khả năng phục hồi.

Laser modules and CMOS imaging modules approach this task differently. Laser scanners typically use a moving beam of light to trace the barcode, detecting reflections and converting them into digital data. CMOS imaging modules, on the other hand, capture a full image of the code using a sensor array, then decode it through onboard processing.

Laser Scanning Modules: Strengths and Trade-offs

Laser modules have a long history in industrial applications. Their scanning beam excels at reading 1D barcodes and performing long-range decoding. In dusty or low-light conditions, the focused beam remains visible and reliable.

From a cost perspective, laser modules often present a lower initial investment, particularly for basic scanning tasks. Their narrow scan line allows high-speed decoding when codes are well-printed and aligned.

Tuy nhiên, lasers face limitations with complex 2D codes like QR codes. Reading speed may decrease when handling damaged or poorly printed labels. Ngoài ra, moving parts inside laser scanners introduce potential wear points, reducing long-term durability in high-vibration environments.

CMOS Imaging Modules: Advantages and Limitations

CMOS imaging modules use solid-state sensors to capture an entire code in one frame. This allows them to decode 1D, 2D, and QR codes quickly, even when the code is damaged, distorted, or printed at low contrast. Their ability to read from screens and curved surfaces has expanded their role in industries embracing digital and mobile-based barcoding.

In terms of precision, CMOS modules excel because they rely on image processing rather than beam alignment. They can capture multiple codes simultaneously and support advanced features like image archiving for traceability.

While their cost is generally higher than basic laser modules, CMOS scanners offer better ROI in multi-format, high-volume environments. With no moving parts, they provide exceptional durability and withstand harsh industrial conditions better over time.

Cost Comparison in Real-World Scenarios

Cost considerations extend beyond the initial purchase. Laser scanners may be more affordable to deploy initially, but maintenance and potential replacements from wear can increase total cost of ownership. In contrast, CMOS imaging modules, though more expensive upfront, often reduce long-term expenses through lower maintenance and multi-purpose functionality.

Ví dụ, a warehouse processing only 1D barcodes on stable surfaces may find laser modules cost-effective. Tuy nhiên, an e-commerce fulfillment center scanning mixed 1D and QR codes from packages, labels, and digital screens would benefit more from the versatility of CMOS imaging technology.

Precision and Performance Differences

In precision-critical workflows, such as electronics manufacturing or medical device assembly, CMOS modules offer higher tolerance for code imperfections. They can decode under extreme angles, varying distances, and inconsistent lighting. Laser modules, while precise under optimal conditions, can be affected by surface reflectivity or misalignment.

High-speed conveyor systems may favor CMOS scanners due to their ability to capture multiple frames per second, ensuring accurate reads even when products move rapidly through the scan zone.

Durability in Harsh Industrial Environments

Durability in Harsh Industrial Environments

Durability is essential when scanners operate in extreme conditions. Laser scanners, with their moving mirrors and mechanical assemblies, are more susceptible to damage from vibration and shock. Over time, this can lead to calibration drift or mechanical failure.

CMOS imaging modules, built with solid-state components, are inherently more resistant to impact, dust, and temperature fluctuations. Their sealed designs reduce the risk of contamination, which is a crucial factor in food processing, chemical manufacturing, and outdoor logistics hubs.

Integration and Future-Proofing

Both laser and CMOS modules can integrate into fixed-mount or handheld industrial QR code scanners. Tuy nhiên, CMOS modules often support firmware updates that extend their capabilities, such as adding support for new symbologies or improving decoding algorithms. This adaptability makes them more future-proof in industries where barcode standards are constantly evolving.

Laser modules remain relevant in applications where simplicity, long-range 1D scanning, and low cost dominate. Yet, as industries continue to adopt 2D codes and hybrid labeling systems, the flexibility of CMOS modules aligns better with long-term trends.

Phần kết luận: Choosing the Right Module for the Job

The choice between laser and CMOS imaging modules in industrial QR code scanners depends on application-specific factors. Laser scanners deliver reliable, cost-effective performance for straightforward, controlled environments, while CMOS modules provide unmatched versatility, Độ chính xác, and durability in dynamic, multi-code industrial workflows.

For Lonvill, delivering both technologies within a unified product portfolio ensures clients can select solutions that align with operational priorities and budget constraints. By understanding the nuanced differences in cost, Độ chính xác, and durability, decision-makers can maximize ROI and ensure consistent scanning performance in demanding industrial settings.

Để lại một câu trả lời