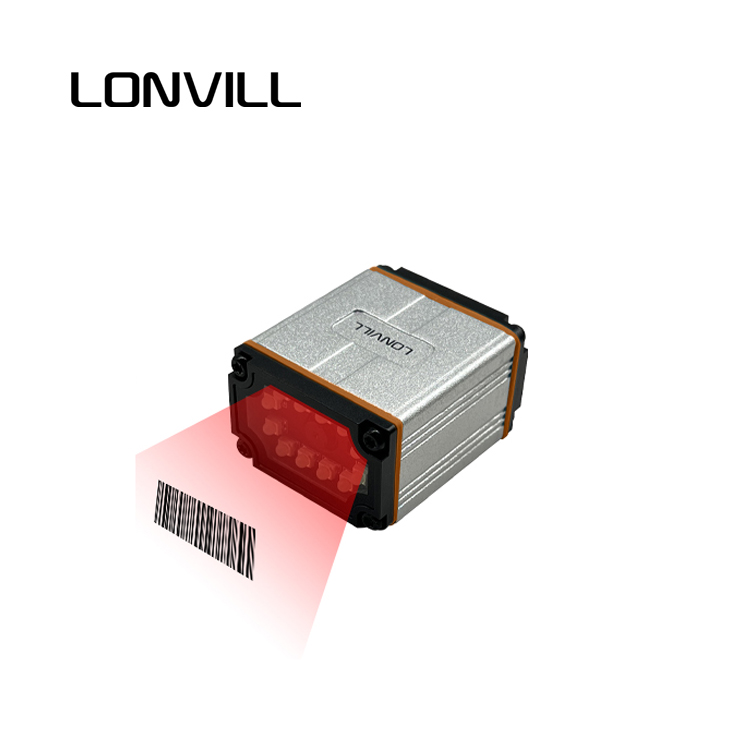

Scanner de codes à barres fixes de petite taille A65-SR

Scanner de codes-barres fixe industriel A65-SR: Equipé d'un 1,3 mégapixels (1280×800) capteur CMOS à obturateur global, cette solution de décodage industrielle intègre un réseau d'éclairage programmable à 12 zones. Conçu pour les géométries de surface difficiles, il offre des performances de numérisation déterministes sur les finitions spéculaires et les substrats incurvés. Les algorithmes propriétaires de reconstruction de code adaptatif garantissent une interprétation fiable des symbologies compromises présentant des dommages ou des différentiels de contraste ≤ 30 %. La capacité de décodage à haute vitesse maintient une intégrité de lecture sans compromis à des vitesses de transit linéaires de 2 m/s..

- Pixel: 1280 (H) * 800 (V) Com.

- Grade de protection: IP65

- Précision de lecture: 1D: ≥3 mil ; 2D: ≥5 mil

- Angle de vision: Horizontal 46 ° (H), vertical 29 ° (V)

- Dimensions: 36(W)*38(D)*24(H)(MM)

- Poids: ≈85 g (à l'exclusion des câbles)

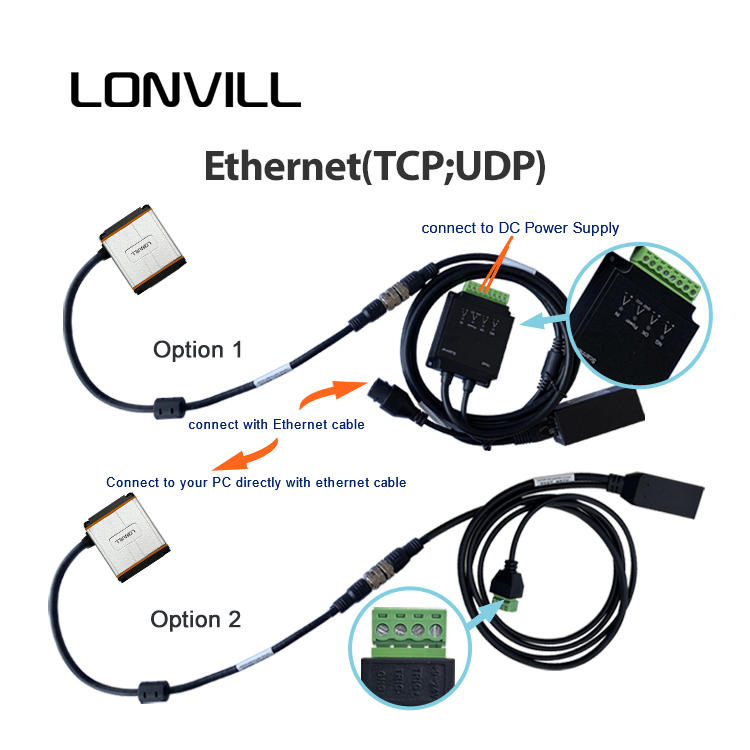

- Interface: RS-232 / USB (Se cacher ; CDC)/RS-232 au port réseau

- Certification: FCC Part15 Classe B,CE,Classe B EMC

- Mode de lecture: Mode clé, détection automatique, balayage continu, Courage d'importance

Caractéristiques

Scanner de codes-barres fixe de petite taille A65-SR pour l'automatisation

Solution de codes-barres compacte pour les demandes industrielles

Le lecteur de codes-barres fixe A65-SR offre un décodage robuste pour les applications automatisées. Il utilise un capteur CMOS 1,3 MP à obturation globale qui capture des détails précis avec des vitesses d'obturation rapides. Son petit facteur de forme s'adapte aux espaces restreints des systèmes industriels. L'unité résiste aux environnements d'usine difficiles tout en fournissant des résultats précis et cohérents. Avec protection IP65 et boîtier en aluminium robuste, il résiste à l'exposition à la poussière et à l'eau. Les installateurs intègrent facilement l'appareil dans les lignes d'automatisation existantes, gain de place et de temps de maintenance.

Performance adaptative dans des scénarios complexes

Ce scanner offre un décodage inégalé dans des conditions difficiles. Son moteur de décodage adaptatif exclusif lit les éléments usés, courbé, et codes-barres à faible contraste. L'éclairage intelligent utilise un système LED à 12 zones pour ajuster l'intensité par section. Les ingénieurs bénéficient d'un contrôle dynamique de la lumière pour optimiser le contraste sur les surfaces réfléchissantes ou courbées. Qu'il s'agisse d'un PCB brillant ou d'une seringue arrondie, l'A65-SR fournit des analyses précises en millisecondes.

Vitesse et précision au cœur

La compensation de mouvement permet à l'A65-SR de capturer des codes jusqu'à 2 mètres par seconde. Il maintient la précision de la numérisation sans perdre la synchronisation sur les lignes à évolution rapide. L'architecture de décodage à grande vitesse traite les symboles sans délai. Même les codes-barres petits ou dégradés sont décodés de manière fiable. Les opérateurs évitent les nouvelles analyses, réduire les interruptions de processus. Le dispositif améliore l'efficacité de la sortie et garantit l'intégrité du code en cas de transit rapide.

Intégration flexible dans tous les secteurs

Le lecteur de codes-barres fixe A65-SR prend en charge plusieurs environnements d'automatisation. Vous pouvez le déployer dans les lignes électroniques SMT, fabrication de panneaux solaires, assemblage de dispositifs médicaux, ou usinage CNC. Il fonctionne aussi bien dans les stations de conditionnement que sur les bancs de tests ATE. Utilisez-le pour confirmer l'identité de la pièce, valider l'assemblage, ou faire correspondre les données de traçabilité. Les développeurs peuvent configurer les zones d'analyse et personnaliser le déclenchement en fonction du flux du système..

Des performances fiables et un contrôle intelligent

Les ingénieurs bénéficient de zones d'éclairage programmables. Cela permet un ciblage précis des zones de code complexes. Sa taille compacte s'adapte aux bras robotisés, bandes transporteuses, et chambres d'essai fermées. Le scanner nécessite un calibrage minimal grâce au réglage automatique de la luminosité. L'installation prend quelques minutes à l'aide de simples points de montage et de ports d'interface. L'algorithme de Lonvill garantit une sortie lisible même sur des substrats sous 30% contraste. Aucun PC supplémentaire requis pour le prétraitement. Les intégrateurs de systèmes apprécient la faible consommation d'énergie et la stabilité de la sortie.

Caractéristiques

| Pixel | 1280 (H) * 800 (V) Com. |

| Éclairage | Source de lumière rouge |

| Se concentrer | Green Biming LED |

| Mode de lecture | Mode clé, détection automatique, balayage continu, Courage d'importance |

| Système de code | 2D: Matrice de données , Code QR , Micro QR,PDF417, Micro pdf417 maxicode, Aztèque |

| 1D: UPC A , UPC E , Ean 8 , Ean 13 , Code 128 , Code 39 , Code 93 ,Code 32 , Code11 , Codabar ,Pilier , MSI , Entrelacé 2 de 5 ,Iata 2 de 5 , Matrice 2 de 5 , Droit 2 de 5 , Pharmacode , RSS-14 ,RSS-14 s'est étendu , RSS-14 Limité , Code composite-A ,Code composite-b , Code composite-C | |

| Précision de lecture | 1D: ≥3 mil ; 2D: ≥5 mil |

| Profondeur de champ | Code 39 (4mil) 40mm ~ 110 mm |

| Matrice de données(10mil) 35mm ~ 300 mm | |

| 100% UPCA (13mil) 35mm ~ 300 mm | |

| Angle de vision | Horizontal 46 ° (H), vertical 29 ° (V) |

| Contraste d'impression | ≥20% |

| Dimensions | 36(W)*38(D)*24(H)(MM) |

| Poids | ≈85 g (à l'exclusion des câbles) |

| Interface | RS-232 / USB (Se cacher ; CDC)/RS-232 au port réseau |

| Mode rapide | Ronfleur, Voyant LED |

| Tension de travail | DC 5V à 24V ± 5% (connecté à la boîte de commande d'E / S) |

| Courant de travail | 300 ma ± 5% (valeur typique), 450 ma ± 5% (valeur maximale) |

| Courant de veille | 100 ma ± 5% |

| Sortie externe | 2-Sortie isolée de couple optique de canal (Bien; “De” |

| Déclencher l'optocoupleur d'entrée | 1-Couple optique de canal Entrée isolée (Npn / png / relais) |

| Température de travail | -20℃ ~ + 50 ℃ |

| Température de stockage | -40℃ ~ + 70 ℃ |

| Humidité relative | 5% à 95% (Pas de condensation) |

| Protection électrostatique | ± 20 kV (perfectionnement de l'air), ± 8 kV (décharge directe) |

| Hauteur de chute | 1.5M |

| Grade de protection | IP65 |

| Certification | FCC Part15 Classe B,CE,Classe B EMC |