Scanning Technology Is Evolving Rapidly

In a data-driven economy, real-time tracking is critical. Across industries, fixed barcode matrix scanners are becoming vital. These scanners are no longer just for retail. Today, they are embedded in manufacturing, Logistik, and healthcare.

This shift is not by chance. Genauigkeit, Geschwindigkeit, and integration define modern systems. And fixed barcode matrix scanners deliver all three. Their versatility fuels the growing trend toward automation and traceability.

What Are Fixed Barcode Matrix Scanners?

A fixed barcode matrix scanner is a stationary device that reads both 1D and 2D barcodes. Unlike handheld models, they are installed into equipment, conveyor systems, Kioske, or access points.

Typically, these scanners:

- Operate continuously without user interaction

- Support high-speed, high-volume environments

- Deliver real-time data to ERP or MES systems

- Use embedded vision for enhanced recognition

This technology excels where stability, consistency, and hands-free operation are required.

Retail Scanning Solutions: Checkout and Beyond

In retail, efficiency is king. Fixed barcode matrix scanners help automate checkout processes, price verification, and inventory control.

Major retailers install them at self-checkout stations and smart shelves. These devices:

- Instantly scan multiple item types

- Integrate with POS and loyalty systems

- Offer seamless omni-channel logistics

Zusätzlich, embedded matrix scanners enable smart lockers and vending machines. These solutions are reshaping modern retail.

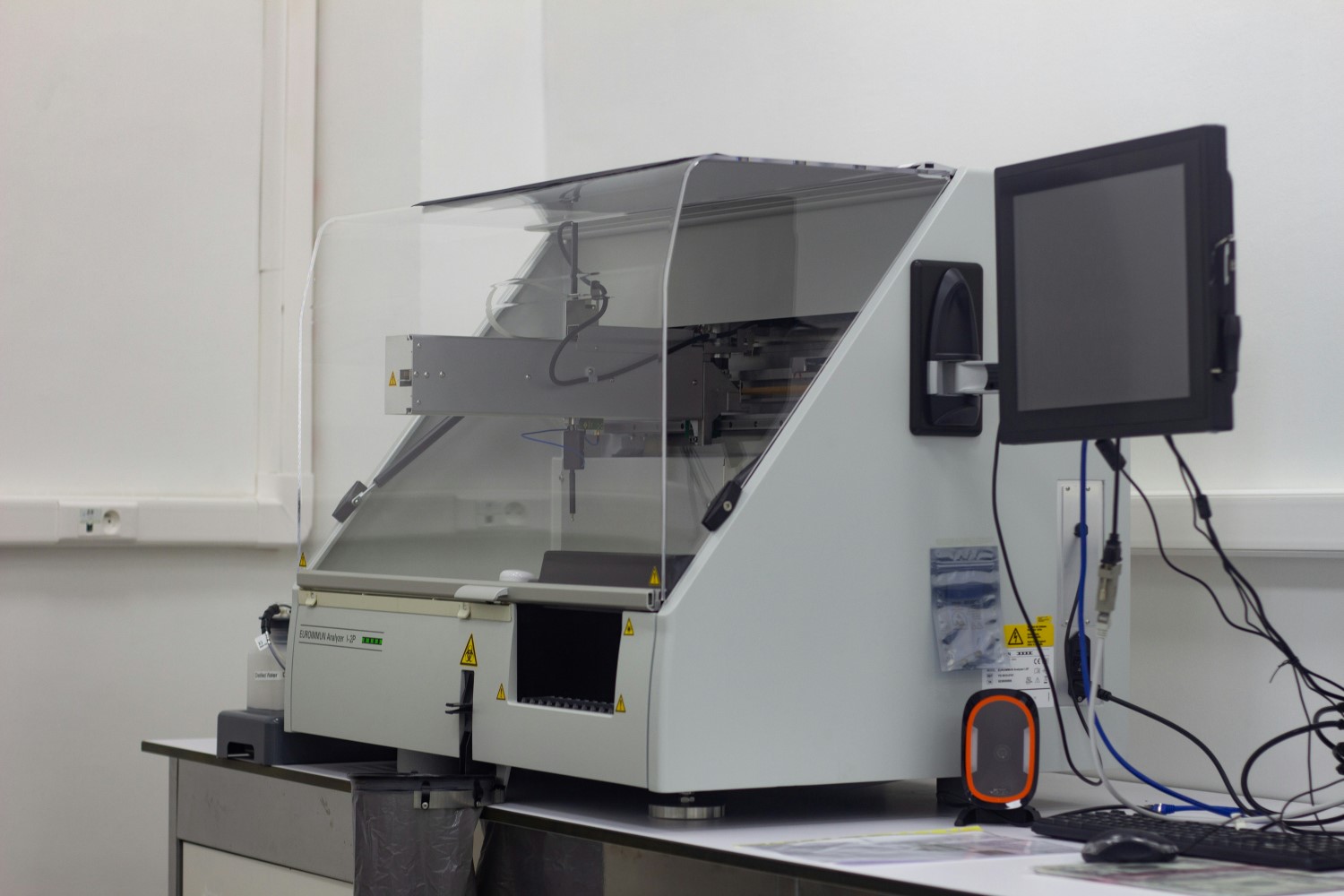

Healthcare: Precision and Hygiene in One

In hospitals and labs, accuracy and hygiene matter. Multi-industry barcode scanners support medical labeling, sample tracking, and patient ID management.

They read small barcodes on:

- Syringes and vials

- Medical wristbands

- Lab sample tubes

Because they are fixed and contactless, cross-contamination risk is minimized. Darüber hinaus, they integrate well with electronic medical record systems (EMRs).

Manufacturing & Automation: Boosting Speed and Accuracy

Smart factories rely on automation. Fixed barcode matrix scanners are key in assembly lines, robotic stations, and packaging units.

They provide:

- Non-stop part verification

- Inline quality assurance

- Traceability of work-in-progress (WIP)

These scanners support Industry 4.0 by connecting devices via industrial protocols like Modbus, Ethernet/IP, or Profinet.

Logistik & Warehousing: Real-Time Package Visibility

Warehouses need accuracy at speed. Barcode scanning at every stage ensures reliable delivery. Fixed matrix scanners are installed on sorting conveyors and picking stations.

Benefits include:

- Automated SKU tracking

- Accurate inventory updates

- Fast returns processing

Even in dim or high-motion environments, these scanners perform consistently.

Public Access & Ticketing: Smart Entry Systems

In metros, amusement parks, and buildings, embedded matrix scanners streamline access control.

Anwendungen:

- Ticket validation at gates

- QR code scanning at turnstiles

- Secure document verification

They read screen-based and printed codes quickly, even from worn or damaged media.

Embedded Design: Compact and Reliable

Modern embedded matrix scanners are small yet powerful. Designed for integration, they offer:

- Compact footprints for tight installations

- Staub- and water-resistant housing

- Long lifespans with minimal maintenance

Some models include autofocus, high frame rates, and adjustable lighting for dynamic surfaces.

Advantages of Fixed Barcode Matrix Scanners

Across sectors, fixed scanners offer core advantages:

- Always-on operation: No human activation needed

- Fast read speeds: Ideal for high throughput

- High accuracy: Supports small, dense, or damaged codes

- Seamless integration: Connects to backend systems

- Flexibility: Works with different barcode types and lighting

As industries digitize, these benefits fuel adoption.

Use Case: High-Speed Conveyor System

A global e-commerce brand integrated the scanners across its fulfillment centers. These devices scan items as they move at 2 m/s.

Project results:

- 99.8% scan accuracy

- 25% reduction in manual interventions

- Full API integration with WMS

Downtime dropped. Operational throughput improved. Customer satisfaction rose.

Use Case: Hospital Specimen Management

A major hospital adopted embedded matrix scanners for its pathology lab. Specimens were tagged and scanned at every step.

Outcomes:

- 100% traceability of lab samples

- Reduction in mislabeling errors

- Seamless EMR integration

The project became a model for regional digital health initiatives.

Sustainability and Longevity

Our fixed barcode scanners use energy-efficient components. They are designed for minimal power draw and reduced emissions.

Long-life LEDs and fanless designs reduce failure risk. Most units operate maintenance-free for over 30,000 hours.

Abschluss: Barcode Innovation Across All Industries

From point-of-sale to production lines, fixed barcode matrix scanners are becoming indispensable. They bring automation, accuracy, and intelligence to digital operations.

Lonvill continues to lead with durable, customizable, and high-performance solutions. Whether you’re in retail, Gesundheitspflege, or manufacturing, we have a scanner designed for your workflow.

Hinterlasse eine Antwort